Procedure style can affect the dimensions with the microbial populace and a chance to clear away it. Useless legs, lengthy pipework runs to taps, undrainable pipes, and U-bends may also build microbiological problems.

An motion stage shouldn't be proven at a level reminiscent of the specification. This leaves no room for remedial process maintenance that can stay away from a specification tour. Exceeding a specification is a much more major celebration than an motion stage excursion.

Chilly water units generally use thermoplastic elements because they suffer a lot less biofouling than stainless steel (at low temperatures). Plastic product used to build pipework is often polypropylene or PVDF.

Site of drawings This section specifies exactly where drawings, manuals and technological info provided by suppliers and installers are retained.

WFI is intended for use while in the preparation of parenteral methods. A distillation system is broadly thought of probably the most robust production system for WFI. Mueller features goods which will competently produce WFI by way of a distillation process.

Purified Water— Purified Water (see USP monograph) is used as an excipient in the creation of nonparenteral preparations and in other pharmaceutical purposes, which include cleansing of sure machines and nonparenteral product or service-Speak to factors. Unless of course otherwise specified, Purified Water is also being used for all assessments and assays for which water is indicated (see Typical Notices and Requirements). Purified Water is additionally referenced through the USP&#one hundred fifty;NF. Regardless of the font and letter scenario used in its spelling, water complying Together with the Purified Water monograph is meant. Purified Water will have to satisfy the necessities for ionic and organic chemical purity and have to be shielded from microbial contamination. The minimum high-quality of supply or feed water for your manufacture of Purified Water is Ingesting Water. This resource water could be purified applying unit operations that come with deionization, distillation, ion exchange, reverse osmosis, filtration, or other suitable purification strategies. Purified water programs need to be validated to reliably and persistently develop and distribute water of satisfactory chemical and microbiological high quality. Purified water units that operate less than ambient problems are significantly at risk of the institution of tenacious biofilms of microorganisms, that may be the supply of unwanted amounts of practical microorganisms or endotoxins within the effluent water.

Consumers aren't obligated to use distinct and maybe archaically generated kinds of analytical water the place possibilities with equivalent or far better good quality, availability, or analytical effectiveness may possibly exist. The regularity and dependability for producing these different analytical waters ought to be confirmed as developing the specified characteristics. Also, any alternative analytical water need to be evaluated on an application-by-software foundation from the person to make sure its suitability. Subsequent is often a summary of the various types of nonmonographed analytical waters that are cited within the USP&#a hundred and fifty;NF. Distilled Water— This water is produced by vaporizing liquid water and condensing it in the purer point out. It's used mainly like a solvent for reagent planning, but it is also specified in the execution of other aspects of checks, which include for rinsing an analyte, transferring a test content like a slurry, as a calibration typical or analytical blank, and for examination apparatus cleansing. Additionally it is cited since the starting off water being used for making Substantial Purity Water. For the reason that none of the cited utilizes of this water indicate a necessity for a specific purity attribute which can only be derived by distillation, water Conference the necessities for Purified Water derived by other indicates of purification may be Similarly ideal where Distilled Water is specified. Freshly Distilled Water— Also known as “a short while ago distilled water”, it really is generated in an identical fashion to Distilled Water and should be used Soon after its generation. This means the necessity to avoid endotoxin contamination along with another adventitious kinds of contamination through the air or containers which could arise with extended storage. It is used for getting ready alternatives for subcutaneous take a look at animal injections together with to get a reagent solvent in assessments for which there seems for being no significantly superior water purity wanted that might be ascribable to staying “freshly distilled”. During the “check-animal” use, the time period “freshly distilled” and its testing use imply a chemical, endotoxin, and microbiological purity that could be equally contented by Water for Injection (nevertheless no reference is created to those chemical, endotoxin, or microbial attributes or distinct safety from recontamination).

Cohen sees two major difficulties, nevertheless, that pharma producers need to manage quickly or be confronted with increased operational expenses: ingesting water shortages and inefficient legacy laboratory-centered testing.

Bends in pipework should be as Mild and as several as is possible; faucet points really should be stored to a minimal. Any disruption to the smooth stream of water leads to turbulence, which assists biofilm formation by producing far more prospects for circulating microorganisms get more info to adhere to colonizable surfaces.

Thing to consider also needs to be supplied on the timeliness of microbial enumeration screening right after sample selection. The quantity of detectable planktonic microbes inside of a sample collected inside a scrupulously cleanse sample container will often drop as time passes. The planktonic microorganisms in the sample will have a tendency to both die or to irretrievably adsorb to your container walls lessening the volume of practical planktonic micro organism that may be withdrawn through the sample for screening.

Water-for-injection (WFI) is outlined through the US Pharmacopeia as water purified by distillation or simply a purification method that is certainly equivalent or exceptional to distillation in the removing of chemical substances and microorganisms.

Take note that much less pure plant steam might be used for steam sterilization of nonporous masses, common cleaning and sterilization of nonproduct Get in touch with devices and analytical products, humidification of air in nonmanufacturing locations, the place used being a nonproduct Get hold of warmth exchange medium, and in all appropriate purposes associated with bulk pharmaceutical chemical and API manufacture.

For nonanimal makes use of, water meeting the necessities for Purified Water derived by other means of purification and/or storage intervals could possibly be equally suited where by “just lately distilled water” or Freshly Distilled Water is specified. Deionized Water— This water is produced by an ion-Trade approach in which the contaminating ions are changed with possibly H+ or OH&#one hundred fifty; ions. Similarly to Distilled Water, Deionized Water is used primarily being a solvent for reagent preparing, but It is additionally laid out in the execution of other components of tests, such as for transferring an analyte within a exam course of action, to be a calibration typical or analytical blank, and for take a look at apparatus cleansing. Also, none of the cited uses of the water imply any desired purity attribute which will only be reached by deionization. For that reason, water Conference the requirements for Purified Water that's derived by other means of purification can be equally suitable where by Deionized Water is specified. Freshly Deionized Water— This water is prepared in the same style to Deionized Water, nevertheless since the identify suggests, it is being used shortly soon after its manufacturing. This suggests the need to prevent any adventitious contamination that might happen on storage. This water is indicated for use as a reagent solvent together with for cleaning. As a result of the nature from the testing, Purified Water could possibly be a reasonable different for these purposes. Deionized Distilled Water— This water is produced by deionizing (see Deionized Water ) Distilled Water. This water is used for a reagent in a very liquid chromatography exam that requires a high purity. As a result of the significance of this higher purity, water that hardly satisfies the requirements for Purified Water might not be satisfactory. Large Purity Water (see below) could be a reasonable substitute for this read more water. Filtered Distilled or Deionized Water— This water is actually Purified Water made by distillation or deionization that has been filtered through a 1.two-µm rated membrane. This water is used in particulate matter tests where the presence of particles inside the water could bias the examination final results (see Particulate Make a difference in Injections

Waters made by other means or managed by other examination characteristics might equally fulfill the supposed makes use of for these waters. It's the person's responsibility to ensure that these kinds of waters, even if made and managed particularly as mentioned, be ideal for their meant use. Anywhere the expression “water” is used in just this compendia without having other descriptive adjectives or clauses, the intent is usually that water of no significantly less purity than Purified Water be used.

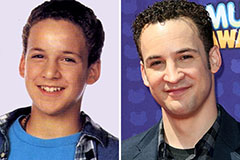

Ben Savage Then & Now!

Ben Savage Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!